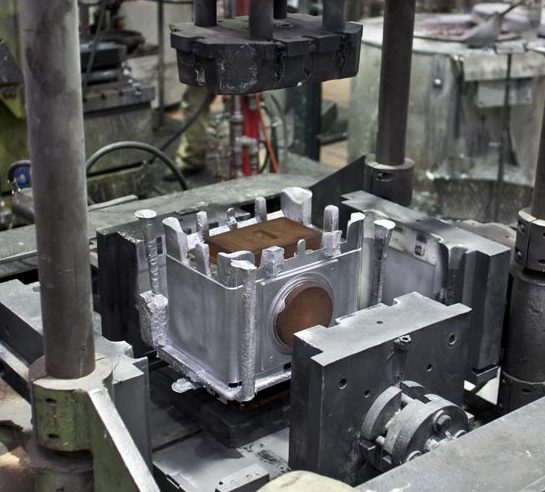

Series shell casting

Chill casting, mass production of your aluminium parts

Chill casting the production of your aluminium parts, our know-how at the service of our customers. LOR ALU started out as a subcontractor for die-cast parts. Our company can meet your requirements with all its experience.

+ productivity for your aluminium parts

+ quantity, for batch runs of 100 pieces or more.

Very good dimensional tolerances

LOR ALU's expertise in Metal Mould Shell Casting Mass Production of Aluminium Parts

Mass production of aluminium parts

Chill casting is designed for the production of aluminium parts (quantity: 100 to 1000 parts/batch), aluminium parts between 0.1Kg and 20Kg. The surface finish of the part is smoother than in sand casting. The metal moulds are designed to be used for several decades.

Advantages :

- Excellent dimensional tolerances

- Repeatability of parts

- Durable tooling (steel)

- Production of parts with recesses (sand core)

- Quantity for series of aluminium parts

The advantages of mass-produced shell casting

1. Precision :

Metal moulds offer high precision for the reproduction of fine and complex details, guaranteeing high quality parts.

2. Durability :

The metal moulds are designed to withstand high production cycles, offering exceptional durability.

3. Thermal conductivity :

Metal moulds facilitate temperature control, which is essential for moulding heat-sensitive materials.

4. Repeatability :

The stability of metal moulds ensures high repeatability in part production, reducing variations.

5. Long-term savings :

Although the initial costs of manufacturing metal moulds can be high, they are amortised over large quantities of parts produced, resulting in long-term savings.

6. Variety of alloys :

Metal moulds can be used for the production of various aluminium alloys.

7. Reducing rework :

The precision of metal moulds reduces the need for retouching or subsequent finishing of moulded parts.

8. Speed :

Metal moulds enable faster production cycles than other moulding methods.

9. Consistent quality :

Thanks to their stability, metal moulds offer consistent quality in the parts produced. Chill casting, for the series of aluminium parts, is a guarantee of quality.

10. Adaptability :

Metal moulds can be designed for a variety of applications, from precision casting to mass production.

Shell casting expertise since 1998: LOR ALU, your trusted partner for aluminium parts of unrivalled precision.